A look behind the scenes at Vobra

In our Dutch factory in Veghel we produce daily 180,000 kilos of dog and cat food for our own brands and many satisfied Private Label customers. Our research department and quality service are also located here. In this way we have good control over the quality of our raw materials and end products. Do you want to know how our kibble is made? We explain it step by step.

Entry of ingredients

In order to make high quality and good food, high quality raw materials are required. We only use products whose origins are extensively checked and fully traceable. Raw materials are only purchased from certified suppliers. Quality and safety are therefore guaranteed even before the raw materials are delivered.

Comprehensive checks

Once the raw materials are delivered, they are carefully inspected. The quality department checks the raw materials for contamination, color, odor, macronutrient values, moisture content and hectoliter weight. The control samples are kept for 1.5 years. In total we use over 250 different types of raw materials.

Fresh meat

The fresh meat arrives at Vobra finely minced and well chilled. The temperature at delivery and storage must always remain below 7ºC. Once taken into process, the meat is processed immediately. Various types of meat and fish, such as duck, salmon and beef, among others, are freshly added in the production process. These fresh products are first thoroughly heated in the dispensing process before being added into the preconditioner (the pre-process) of the extruder. The fully automated coupled CIP (Cleaning in Place) system ensures that the entire meat dosing line is cleaned fully automatically afterwards.

Grinding and mixing

The actual production process begins with the weighing of the raw materials. Most raw materials are weighed automatically and in the right quantity and ratio. The smaller quantities of raw materials, the fine components, are added manually.

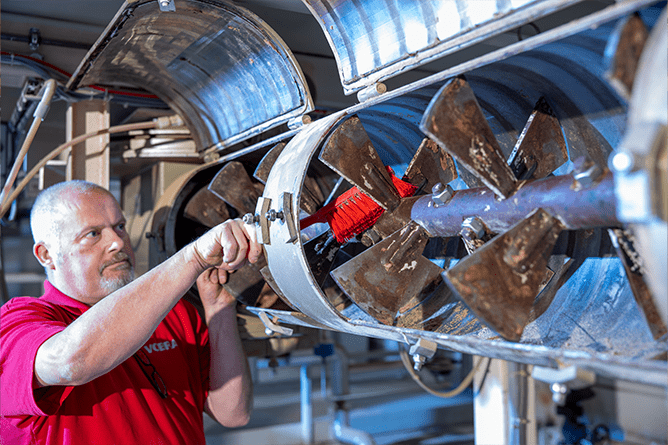

After dosing, the ingredients are ground by hundreds of hammers in the hammer mill until the flour has the prescribed fineness and leaves the hammer mill through the sieve. Vitamins and minerals are added manually and are passed outside the hammer mill so that they remain intact during the production process.

The flour mixture is then mixed in the mixer until it becomes a homogeneous substance. Then the mixture either goes to the press to be pressed or to the extruder to be made into a crispy kibble.

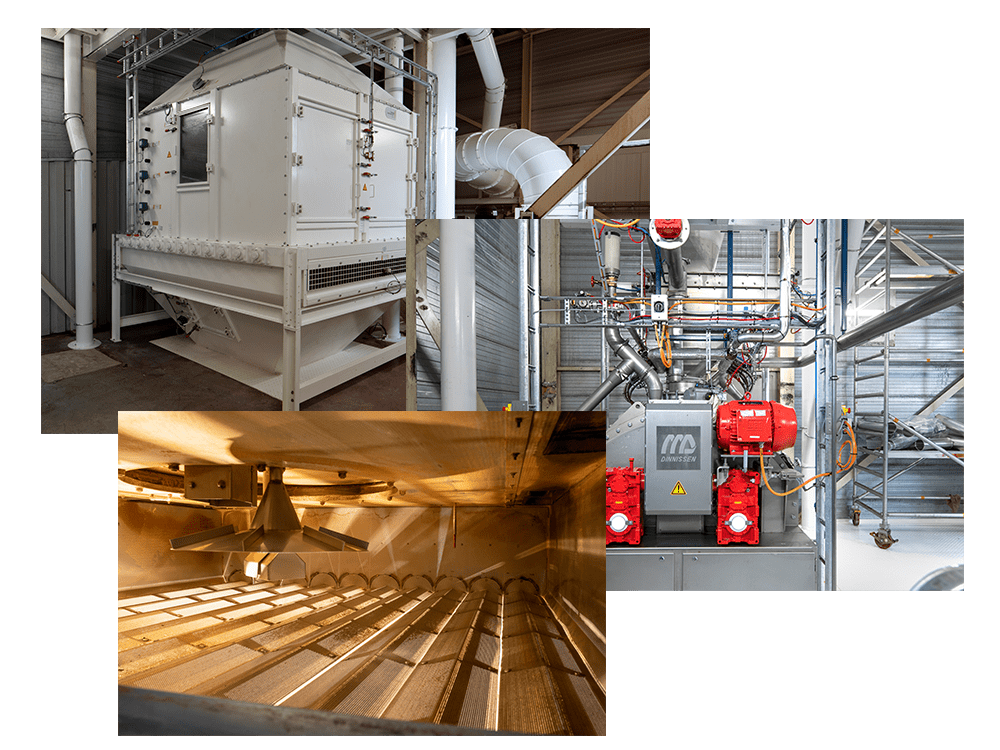

Extruder

After grinding and mixing, the mixture goes to the preconditioner, the pre-process of the extruder. If the recipe involves fresh meat or fish, the fresh product is added at this point in the production process. Then the mixture goes to the extruder where water and steam are added one more time. It is then pressed through a mold and the kibble is cut to the desired thickness. When the kibble comes out of the mold, it expands. It is a kind of a popcorn effect. This process is called extrusion. The mold determines the final shape of the kibble. The rotational speed of the blades determines the thickness of the kibble.

Drying

From the extruder, the kibbles are dried. This is done at a temperature between 80°C and 130°C. Drying is necessary to remove the moisture from the kibbles. Too much moisture in combination with hot kibbles causes mold.

Coating

After drying, the kibbles are coated. In coating, fats and digest are sprayed onto the kibble. In the case of oils and a certain fat content, the vacuum is turned on, so it also partially soaks into the kibble. The fats and digest provide not only energy, but also an attractive smell and taste for dogs and cats.

Cooling

Next, the kibble is cooled to ambient temperature in a cooler. The warm air released in this process is used again in drying the kibble. Drying and cooling is essential to prevent mold.

Press

Recipes for pressed kibbles use pre-developed raw materials so that the kibble is easy to digest. Digest, vitamins and minerals are also added during the grinding and mixing process and then the mixture goes to the press. Digest provides not only energy, but also an attractive smell and taste for dogs. Adding steam additionally unlocks starch and makes the mixture sticky, making it easier to press. The temperature during the pressing process remains lower than during the extrusion process; approximately 70ºC. Our pressing line has a capacity of 2 to 3 tons per hour.

Quality service

Before the kibbles are filled into the packaging, an extensive quality control takes place. First of all, in the visual inspection the chunk is compared to the reference sample for color and shape. Because natural raw materials are used, not all productions have the same color. Raw materials can be darker or lighter in color. Therefore, the final product will also be darker or lighter in color. Secondly, the quality department checks whether the thickness and diameter of the kibble are within the set margins. Finally, the NIR analysis takes place. NIR stands for Near Infra Red. During the NIR analysis the analytical values are measured, such as crude fat, crude protein, crude fibre, crude ash and moisture content.

Packaging line

On the packaging line, the correct amount of feed is automatically weighed and bagged into a package. Each package is labeled with a unique batch code and an expiration date. The unique batch code on each bag ensures traceability of the finished product back to the individual raw materials used and their origin.

The small packaging line can fill packs from 400 g to 5 kg. On the small packaging line, the packs are stacked automatically with a robot palletizer. The packs are stacked onto pallets either loose or in boxes. The large packaging line can fill packs of 7 kg to 20 kg. Full pallets are automatically sealed and can be sent directly to the warehouse or to the customer.

Both new packaging lines will soon also be able to gas packages. Gas flushing slows down the oxidation process of the feed, which makes it tastier and keeps it a bit longer. This gas flushing is an extra quality which will be further improved technically in terms of speed of the packaging process and stability of the pallets.